-

All Nordent forceps are manufactured of a special stainless steel for maximum performance, longevity and corrosion resistance. All forceps are the American style with hidden pins, unless otherwise noted as "English Pattern" which have visible pins. Most forceps can be ordered with serrartions added along the beaks for increased grip along the tooth surface.

-

All Nordent forceps are manufactured of a special stainless steel for maximum performance, longevity and corrosion resistance. All forceps are the American style with hidden pins, unless otherwise noted as "English Pattern" which have visible pins. Most forceps can be ordered with serrartions added along the beaks for increased grip along the tooth surface.

-

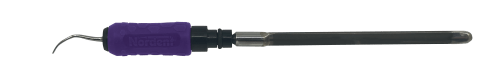

LuxPoint™ ultrasonic inserts that feature our exclusive UltraSteel™ technology, providing enhanced performance and industry-leading tip durability. Recommended for light to heavy deposits. Beveled edges make the triple bend design an excellent choice for stubborn calculus. The triple bend shank allows increased access around line angles and interproximal access. Also great for orthodontic cement removal. Recommended for low-high power or medium-high for tenacious calculus.

-

LuxPoint™ ultrasonic inserts that feature our exclusive UltraSteel™ technology, providing enhanced performance and industry-leading tip durability. Recommended for light to heavy deposits. Beveled edges make the triple bend design an excellent choice for stubborn calculus. The triple bend shank allows increased access around line angles and interproximal access. Also great for orthodontic cement removal. Recommended for low-high power or medium-high for tenacious calculus.

-

LuxPoint™ ultrasonic inserts that feature our exclusive UltraSteel™ technology, providing enhanced performance and industry-leading tip durability. An all-around great choice for a variety of scenarios, in a slim design for maximum subgingival and interproximal access.

-

LuxPoint™ ultrasonic inserts that feature our exclusive UltraSteel™ technology, providing enhanced performance and industry-leading tip durability. An all-around great choice for a variety of scenarios, in a slim design for maximum subgingival and interproximal access.

-

LuxPoint™ ultrasonic inserts that feature our exclusive UltraSteel™ technology, providing enhanced performance and industry-leading tip durability. Designed for subgingival and interproximal surfaces with light to moderate deposits. The thin tip design improves access. The recommended power level is low-medium.

-

These tweezers are specially designed for the placement of brackets in the posterior region. The angle of the tips allow easy access during placement.

-

Multi-use pliers for bending NiTi wire up to .025 (.64mm). Reduce a multi-step process down to one step with these wire-forming pliers. Simply squeeze and you are done; NO heat required. For NiTi wire only.

-

For bending smooth loops on stainless steel wires up to .022 x .025 (.56 mm x .64 mm).

-

For precise forming of 3 mm, 4 mm, 5 mm, and 6 mm loops. Groove at the base aids in closing loops. For use with stainless steel wire up to .022° (.56 mm).

-

Perfect for subtle contouring of stainless steel arch wires up to .030" (.76 mm).

-

Used for placing first, second and third bends on stainless steel wires up to .022 x .025 (.56 mm x .64 mm).

-

Used for placing first, second and third bends on stainless steel wires up to .022" x .025" (.56 mm x .64 mm).

-

Graduated cones .045" - .060" - .075 (1.14 mm, 1.52 mm, 1.91 mm) are designed to form precise omega loops on wires up to .022" x .025" (.56 mm x .64 mm)

-

Most often used for contouring and bending stainless steel wires up to .030" (.76 mm).

-

Designed for tying stainless steel ligature wires up to .015" (.38 mm).

-

Ideal for the fitting of stainless steel crowns and bands.

-

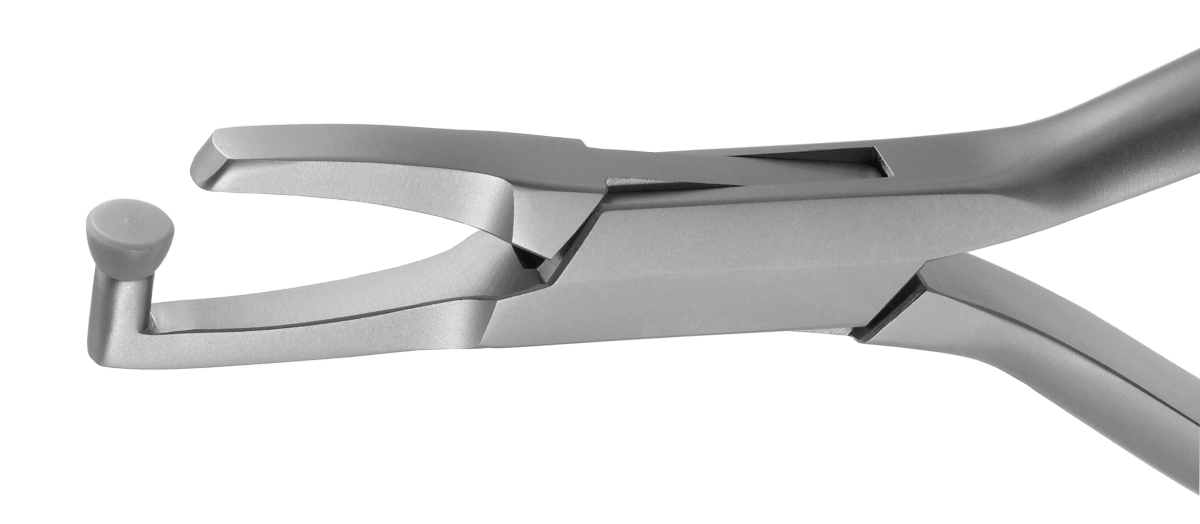

Angled and precisely ground beaks allow for easy removal of all bracket styles in both the anterior and posterior.

-

Slim tipped bracket tweezers with tapered tail to aid in bracket manipulation. The thinner working end gives the clinician greater visibility when bringing the bracket to the patient’s mouth. The thinner back end of the instrument allows for easier manipulation of the bracket’s position by simply turning the instrument. This feature allows for the use of a single instrument in bracket placement.

-

Designed for tying stainless steel ligature wires up to .015° (.38 mm).

-

The offset alignment of tip and occlusal pad is designed for band removal.